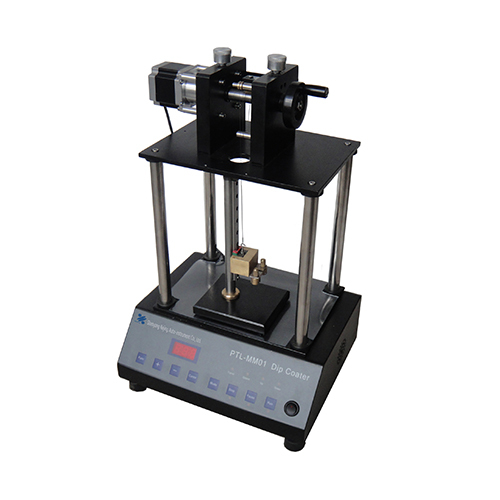

Máquina de revestimento por imersão (1-200 mm/min) com forno de secagem de até 100ºC

1. A máquina de revestimento de elevação de temperatura constante PTL-MMB01 foi especialmente projetada para o estudo de filme epitaxial líquido.

2. A máquina de revestimento de elevação de temperatura constante adota um painel de controle do tipo botão e um computador de placa única para controlar a velocidade de tração do fio para fazer o levantador funcionar de forma suave e precisa.

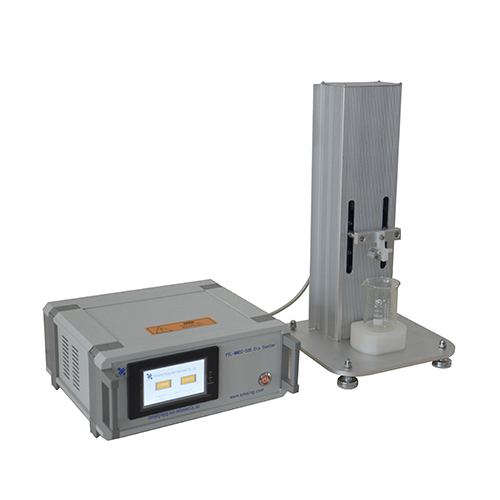

3. A máquina de revestimento de elevação de temperatura constante também pode ser equipada com um forno termostático com temperatura de até 100 ℃, para que o processo de crescimento do filme possa ser realizado em uma temperatura constante.

- Shenyang Kejing

- Shenyang, China

- 10 dias úteis

- 50 conjuntos

- em formação

Introdução da máquina de revestimento de elevação de temperatura constante:

O aplicador de imersão a temperatura constante PTL-MMB01 com forno de secagem para laboratórios de P&D é um equipamento de tração de precisão milimétrica desenvolvido por nossa empresa para o estudo do crescimento em fase líquida de filmes finos em substratos. Possui certificação CE e é um produto e equipamento necessário para unidades e institutos de pesquisa de filmes de crescimento em fase líquida.

O sistema de controle da máquina de revestimento por imersão de temperatura constante com forno de secagem para laboratório de P&D é um sistema de controle de chip único de alta precisão desenvolvido internamente que controla a operação do atuador. O botão manual alterna a direção de tração. A velocidade e o curso de elevação e abaixamento podem ser definidos. O processo de elevação ocorre de forma suave e precisa. A máquina de revestimento por imersão de temperatura constante PTL-MMB01 com forno de secagem para laboratório de P&D puxa a amostra verticalmente por meio de trefilação de cabos, imerge a amostra no material de filme fino em fase líquida por um período de tempo e, em seguida, puxa-a para fora, de modo que uma certa espessura de filme cresça na superfície da amostra. A máquina de revestimento por imersão de temperatura constante com forno de secagem para laboratório de P&D pode imergir a amostra no material de filme fino líquido por meio de controle manual e, em seguida, puxá-la de volta automaticamente. Ela também pode imergir a amostra no material de filme fino líquido por meio de controle automático e puxá-la de volta manualmente. Esta máquina é equipada com um forno de secagem de temperatura constante com uma temperatura de até 100 °C, o que pode garantir que o processo de crescimento do filme seja realizado a uma temperatura constante. Esta série de máquinas é pequena, simples de operar e fácil de transportar, e é amplamente utilizada em laboratórios de faculdades, institutos de pesquisa e unidades corporativas.

Vantagens da máquina de revestimento por imersão programada com temperatura constante:

1. A máquina de revestimento por imersão programada com temperatura constante pode fornecer um ambiente de revestimento por imersão estável com temperatura constante.

2. Todo o processo de revestimento por imersão é realizado em um campo de temperatura constante, o que é propício à formação de filme e cura.

3. A máquina de revestimento por imersão programada com temperatura constante é simples e conveniente de operar e limpar, adequada para iniciantes.

4. A máquina de revestimento por imersão programada com temperatura constante é pequena, econômica e economiza espaço no laboratório.

5. A máquina de revestimento por imersão programada com temperatura constante adota acionamento por motor de passo de alta precisão e tecnologia de tração por condução de fio para redução de vibração.

Parâmetros técnicos da máquina de revestimento de elevação de temperatura constante

Nome do produto | Máquina de revestimento de elevação de temperatura constante PTL-MMB01 | |

Modelo do produto | PTL-MMB01 | |

Condições de instalação | 1. Fonte de alimentação: AC220V 50/60Hz; 2. Ambiente do local: Use em uma temperatura de 25℃±15℃ e umidade de 55%Rh±10%Rh. | |

Parâmetros Principais (Especificação) | 1. Tensão de trabalho da máquina de elevação: DC24V, 3,75A (com adaptador de energia padrão "") 2. Potência da máquina de elevação: 50W. 3. Tipo: tipo de temperatura normal (com caixa de temperatura constante). 4. Motor de acionamento: motor de passo de alta precisão. 5. Faixa de ajuste de velocidade: 1-200 mm/min. 6. Limite superior do curso do suporte deslizante da amostra: 75 mm. 7. Comprimento efetivo de imersão: ≤ 60 mm. 8. Limite superior de carga de elevação:≤ 100g. 9. Tamanho do substrato: 75 mm × 25 mm × 2,5 mm. 10. Parâmetros da caixa de temperatura constante: · Tensão de trabalho: AC220V 50/60Hz. · Corrente nominal: 3,6A. · Potência nominal de aquecimento: 0,8 kW. · Faixa de temperatura: temperatura ambiente RT ~+100℃. · Método de controle/configuração de temperatura: tubo digital de fileira dupla PID/configuração de quatro botões por toque. · Temporizador de operação de aquecimento: 0~9999 minutos ou horas. · Dimensões internas (conteúdo): 310 mm × 310 mm × 310 mm (30 L). · Dimensões externas: 428 mm × 500 mm × 723 mm. | |

11. Especificações do produto: Dimensões: 428 mm × 500 mm × 995 mm. Peso: ≈50 kg (incluindo caixa de temperatura constante). |

| |

Acessórios padrão:

| NÃO. | Nome | Qtd. | Link da imagem |

| 1 | Exemplo de fixação | 1 conjunto | -- |

| 2 | Copo de carregamento | 1 peça | -- |

| 3 | Fio de elevação | 3 itens | -- |

Garantia:

Um ano limitado com suporte vitalício (não incluindo peças enferrujadas devido a condições inadequadas de armazenamento).

Logística:

Sobre nós:

Oferecemos aos clientes uma gama completa de serviços de alta qualidade durante todo o processo de pré-venda e pós-venda. Antes da venda, nossa equipe de atendimento ao cliente fornecerá sugestões profissionais de seleção de produtos e recomendará os produtos adequados com base nas necessidades do cliente. No pós-venda, oferecemos suporte técnico abrangente, incluindo orientação remota para instalação e comissionamento, além de sugestões de manutenção, para ajudar os clientes a concluir seus projetos com sucesso. Buscamos sempre que você se sinta à vontade e satisfeito em todos os momentos.