Como escolher o material certo para a lâmina de serra?

2025-01-27 15:30In metal cutting, it is very important to choose the right saw blade material. Different metal types, hardness and cutting conditions require different saw blade materials to ensure cutting efficiency and tool life. Therefore, how to choose the most suitable metal cutting saw blade material has become a key issue in the processing industry. This article will analyze several common metal cutting saw blade materials in detail, with special emphasis on materials suitable for high hardness and high precision requirements, to help you make a wiser choice.

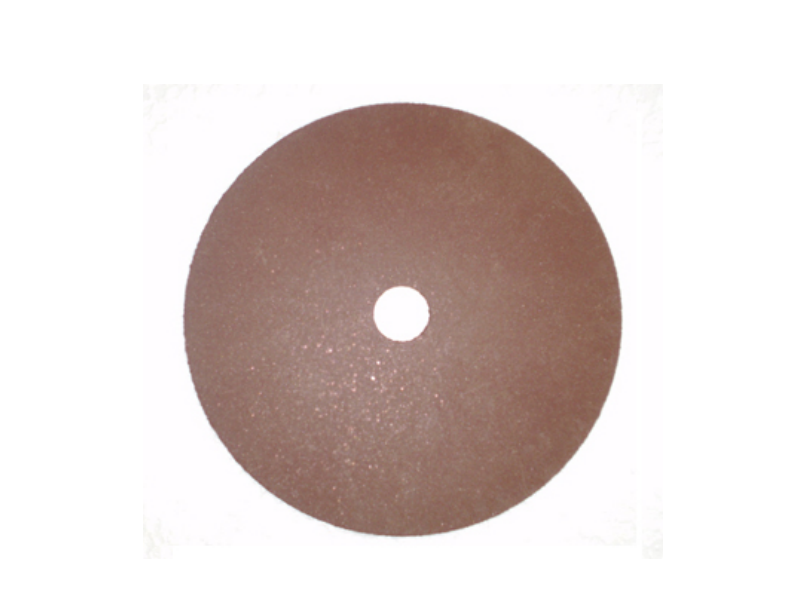

1. Corundum saw blade:

Corundum saw blade is one of the most outstanding metal cutting tools on the market, especially suitable for cutting hard metals, alloys and other high-strength materials. Due to its extremely high hardness and wear resistance, corundum saw blades can maintain stable performance under high temperature and high load cutting conditions, ensuring cutting efficiency and precision. Its durability is outstanding and it can maintain a sharp cutting edge for a long time, which is particularly important when performing precision processing and is suitable for high-demand metal processing tasks.

Corundum saw blade is suitable for cutting stainless steel, alloy steel, aluminum alloy and other metals with high hardness. They can effectively improve production efficiency, and their long service life also greatly reduces the replacement frequency and maintenance costs. If your processing requirements focus on cutting accuracy and tool durability, corundum saw blades are undoubtedly an ideal choice.

2. Diamond saw blades:

Diamond saw blades are widely used in the cutting of superhard materials such as hard metals, ceramics and composite materials. Diamond itself has extremely hard properties in nature, so diamond saw blades have high wear resistance and cutting ability, and can show excellent cutting effects in the processing of high-hardness materials.

Diamond saw blades can not only improve cutting efficiency, but also reduce heat generation and material damage during cutting, ensuring the finish and accuracy of the cutting surface. Especially in the processing of some special metals or materials, the advantages of diamond saw blades are particularly obvious.

When choosing a metal cutting saw blade, in addition to considering the type, hardness and cutting conditions of the metal, it is also necessary to make a comprehensive judgment based on cutting accuracy and processing requirements. For tasks that require precision cutting and higher hardness materials, corundum saw blades and diamond saw blades are undoubtedly more suitable choices. Their ultra-high hardness and excellent wear resistance can ensure higher cutting efficiency and tool life.

For general metal processing, especially in the cutting of medium and low hardness materials, high-speed steel (HSS) saw blades and cobalt-based alloy saw blades can also provide stable performance. When choosing, make the appropriate decision based on your specific needs, combined with the performance of the cutting machine and the special requirements of the cutting task. I hope this article can help you better understand the material selection of metal cutting saw blades and provide more efficient and accurate solutions for your metal processing tasks.